Safety

-

When Should You Do Maintenance and Repairs On Your Machines? Why?

- June 21, 2023

- Posted by: David Marshall

- Category: Manufacturing, Productivity, Safety

No Comments

Your factory’s maintenance program should be ongoing, not as a repair-as-needed reactive process. You need to be as proactive and preventative as possible. Basically, there are two kinds of maintenance you should be doing: 1) Heavy maintenance and 2) Running maintenance. Heavy maintenance:Once a year when you check everything and do all the heavy stuff

-

Your Associates Should Be Your Safety Experts, Not Your Managers

- May 31, 2023

- Posted by: David Marshall

- Category: Management, Manufacturing, Safety

Safety should be the number one priority in any manufacturing plant, but your managers should not be the ones establishing the safety rules. Your associates should be your safety experts, and they should be the ones making the rules and running the safety training program. After all, they’re the ones performing the tasks, and they’re

-

Who Is Responsible for an Individual’s Safety?

- May 24, 2023

- Posted by: David Marshall

- Category: Manufacturing, Safety

When it comes to deciding who’s responsible for an individual’s safety, there’s only one right answer. EVERYONE Anyone near them. Anyone on the other side of the room or the other side of the building. Anyone who happens to be walking by. It’s no one person’s job, it’s everyone’s job. Everyone is responsible for everyone

-

How Much Does a Safety Lapse Cost Your Company?

- May 17, 2023

- Posted by: David Marshall

- Category: Management, Safety

I’ve said before that Safety is my number one non-negotiable. A safety lapse costs money, but most importantly, it can mean an injury to the people working for you. A safety lapse can be as benign as someone cutting their finger or as severe as being killed on the job. The range of costs can

-

A Machine Isn’t Designed to Leak

- May 10, 2023

- Posted by: David Marshall

- Category: Manufacturing, Safety

Go into any manufacturing space, and you’ll often see pits around pieces of equipment that are like retention ponds, soaking up leaks. It could be oil, water, or hydraulic fluid. In fact, in many manufacturing spaces, you’ll see leaks like this. They have to build those pits in place because there will invariably be leaks

-

How Do You Manage a Disruptive Employee, Especially in a Union?

- November 10, 2021

- Posted by: David Marshall

- Category: Business, Leadership, Management, Safety

One of the most difficult things to do in a manufacturing operation is to fire union employees. Unions have historically played an important role in establishing workers’ rights and guaranteeing their safety. But there are some workers who take advantage of the union and hide behind it when they’ve been doing poor quality work or

-

Stay Focused on Employee Health & Safety

- June 16, 2021

- Posted by: David Marshall

- Category: Management, Safety

As a manufacturing manager, the worst words you can hear are “workplace injury.” Manufacturing is not necessarily a safe job, and people can get hurt just doing their work. Even with all the employee health and safety training, policies, and personal protective equipment, people can still get hurt on the job. That creates a lot

-

Can you Require Employees to Get the COVID Vaccine?

- May 26, 2021

- Posted by: David Marshall

- Category: Management, Safety

The COVID vaccine is in full swing and is fully available in every state in the U.S., but there are still plenty of people who are “vaccine hesitant” or are unsure whether they should get it or not. For manufacturers and businesses where remote work isn’t possible, the question is whether a company can require

-

Why You Need to Hire Outside Experts

- April 14, 2021

- Posted by: David Marshall

- Category: Management, Safety

When I got involved with Robroy back in 1995, they had many environmental problems. They had just gotten out of the galvanizing business, which has an awful lot of hazardous waste to deal with. It’s an environmental nightmare. I had (and still have) zero experience in environmental matters and environmental rules change on a minute-to-minute

-

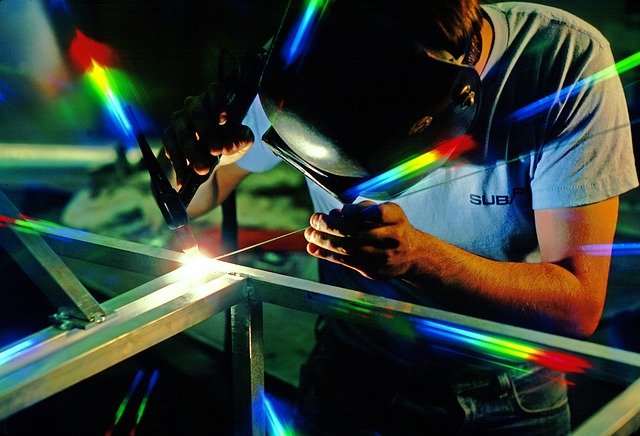

How Important is Ongoing Safety Training in a Manufacturing Operation?

- February 10, 2021

- Posted by: David Marshall

- Category: Manufacturing, Safety

Ongoing safety training is critical in any manufacturing operation. It’s not just a one-and-done, set it and forget it type of operation. Safety training is absolutely essential because your first priority in your business is human life. You absolutely, positively have to protect that above everything else; there are no two ways about it. Protecting