- May 10, 2023

- Posted by: David Marshall

- Category: Manufacturing, Safety

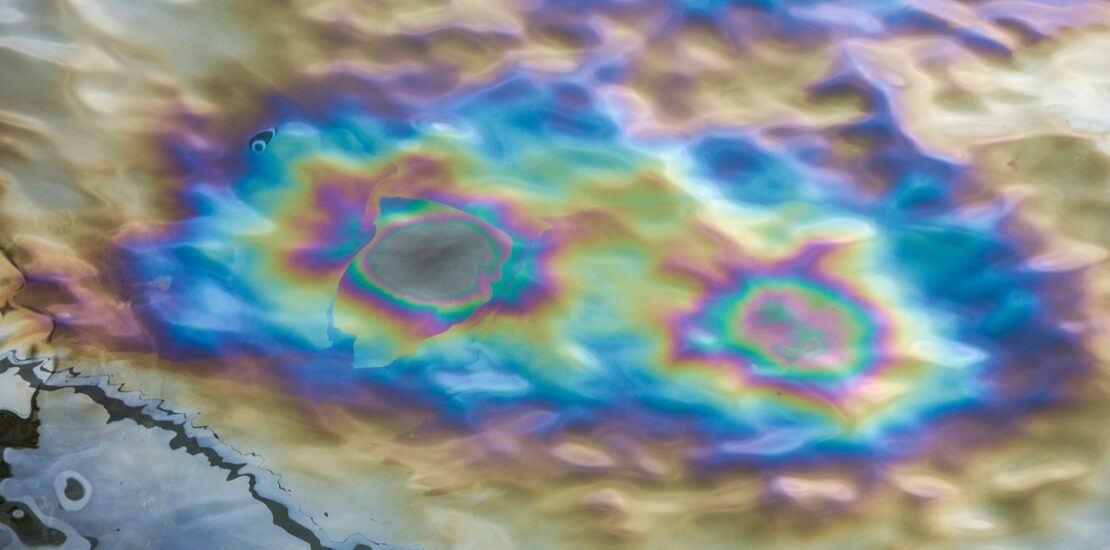

Go into any manufacturing space, and you’ll often see pits around pieces of equipment that are like retention ponds, soaking up leaks. It could be oil, water, or hydraulic fluid. In fact, in many manufacturing spaces, you’ll see leaks like this. They have to build those pits in place because there will invariably be leaks in the big machines they use.

But the truth of the matter is that a machine isn’t designed to leak. There’s nothing in the designer’s specs that show a place for leaks to occur.

Instead, a leak is a leading indicator of a different problem. Get to the cause of a leak, and you’ll solve a lot of expensive problems down the road. It could be a bearing that’s starting to go or a hose that’s beginning to crack. But the longer you leave it, the worse it’s going to get.

So get to the source of the leak as soon as you possibly can. You’ll solve a hell of a maintenance problem, and more importantly, you solve a Housekeeping and Safety Issue.

Basically, if you don’t contain the leak, it will spread, and people can slip on it. That’s Housekeeping and Safety in a nutshell.

Or you may fail to repair a leak, and the machine can get damaged and shut down for days and weeks. That’s a Productivity issue. You hoped to save a few bucks by ignoring the leak, but instead, your bad decision is now costing you thousands of dollars per day. That’s what we English call “penny-wise and pound foolish.”

Or you may fail to repair a leak, and the machine can get damaged and shut down for days and weeks. That’s a Productivity issue. You hoped to save a few bucks by ignoring the leak, but instead, your bad decision is now costing you thousands of dollars per day. That’s what we English call “penny-wise and pound foolish.”

Housekeeping and Safety are Two of My Non-Negotiables

I’ve talked in the past about Safety and Housekeeping being two of my non-negotiables. That means I won’t compromise on their execution or standards.

- Safety: Everyone needs to follow all safety rules at all times or be fired. Safety rules should be decided by the associates who do the work, not by the managers who don’t. Everyone should receive safety training.

- Housekeeping: If something is out of place, fix it. It’s not one person’s job, it’s everyone’s job. If something is on the floor, pick it up. If something is in a pathway, move it to where it should be.

Bottom line: If you have a leak, that’s a Housekeeping issue. You need to clean up the leak immediately so people don’t slip. That becomes a Safety issue.

Leaks Indicate a Bigger Problem

More importantly, leaks are a bigger indicator of a problem in a company. It’s basically the Broken Windows Theory.

Broken Windows Theory was first shared in 1982 in The Atlantic Monthly:

Social psychologists and police officers tend to agree that if a window in a building is broken and is left unrepaired, all the rest of the windows will soon be broken. . . one un-repaired broken window is a signal that no one cares, and so breaking more windows costs nothing.

In other words, if you’re willing to put up with leaks, you’ll put up with anything. You’ll put up with increased scrap and rejects. You’ll put up with broken-down machines and significant downtime. You’ll put up with horsing around and rampant safety violations. And you’ll put up with lost revenues and decreasing profits.

By paying attention to the smaller problems, you’ll eliminate the bigger problems. It sends the message to your staff that you don’t want the bigger problems in the first place. By paying attention to the smaller problems, you’ll get the operators to pay attention to details, and make it their responsibility to shut down the machine and get maintenance to solve them. And if the operator doesn’t see it, someone else will point it out.

The small problems could even indicate a problem with an associate or the system, especially if it happens more than once. It could be the operator, the machine itself, or a signal of very poor maintenance. That’s why it’s important to track and measure your maintenance.

Because to solve a leak problem, you have to take the equipment down, which means a stop in production. Measuring downtime and its causes is important because if you have a machine consistently going down for the same issue, then you’ve got a different kind of problem.

In short, leaks in a machine can lead to leaks in profits, because you’re willing to put up with leaks elsewhere. Keep an eye on the leaks and fix them as soon as they start. Because a machine is not supposed to leak.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business, including pivoting within their industry. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

Photo credit: Dennis F. Larsen (Pixabay, Creative Commons 0)