Innovation

-

Advanced Strategies for Creating a Lean Manufacturing System

- July 24, 2024

- Posted by: David Marshall

- Category: Digital Transformation, Innovation, Manufacturing

No Comments

You’re no doubt already familiar with lean manufacturing, as it’s now one of the most common manufacturing philosophies today. And even if you haven’t, you’ve heard about its core principles: reducing waste, improving efficiency, and maximizing your value to the customers. But lean is more than just eliminating waste or Jack Sprat’s wife’s dietary restrictions.

-

Creating a Sustainable Manufacturing Operation

- July 17, 2024

- Posted by: David Marshall

- Category: Innovation, Manufacturing

Sustainable manufacturing is no longer a buzzword, it’s a business imperative. It’s about balancing environmental responsibility, economic viability, and social equity. It means fulfilling your fiduciary responsibilities to your associates and your customers. It means avoiding harming the environment and earning expensive and painful fines and penalties. And it means being good corporate and business

-

Building a Winning Team: Continuous Improvement and Development

- July 7, 2024

- Posted by: David Marshall

- Category: Business, Innovation, Measurement, Productivity

Every manager dreams of building a winning team. Every boss dreams of having a winning department. Every sergeant dreams of commanding a winning squad. Members doing the high-quality work that needs to be done, fulfilling every function, completing every pass, every play, every task, every order, and functioning as a single unit with a single

-

How to Stay Competitive in a Global Market

- April 24, 2024

- Posted by: David Marshall

- Category: Innovation, Management

We are truly in a global market these days, and the cost of production in the United States makes cheaper overseas production much more attractive to a lot of buyers. Despite the push to “Buy American” and other campaigns, overseas manufacturers are slashing costs and paying their workers a less-than-optimal wage. That makes it a

-

Use Inside and Outside Experts for a Major Undertaking

- September 13, 2023

- Posted by: David Marshall

- Category: Innovation, Leadership

Manufacturing CEOs and COOs often deal with company-wide changes and projects that can affect how the entire business operates. One question we often dealt with at Robroy was whether to enlist the services of external experts during these challenges. The decision to bring in outside expertise can be a game-changer. There were times, like when

-

Adopt a change management strategy when going through a major undertaking

- September 6, 2023

- Posted by: David Marshall

- Category: Digital Transformation, Innovation, Leadership

Years ago, when I worked at Robroy, our company never had a proper warehouse management system — software that tracked our inventory and helped us know what we needed to order and what we had too much of. Our raw materials and our products would just sit on the floor and oftentimes got damaged. Not

-

How Can Leaders Prepare for Changes in Modern Manufacturing?

- August 23, 2023

- Posted by: David Marshall

- Category: Digital Transformation, Innovation, Manufacturing

The modern manufacturing industry is undergoing seismic shifts, especially in the last decade. But adapting to these shifts isn’t optional — it’s critical if you’re going to survive and succeed. So how do you navigate these changes without losing your way? How can a modern leader adapt to the changes in modern manufacturing? Do you

-

Increasing Productivity Doesn’t Always Mean Working Harder

- June 14, 2023

- Posted by: David Marshall

- Category: Innovation, Management, Manufacturing, Productivity

As much as I hate to say it, the key to increased productivity really is “work smarter, not harder.” But it’s more than just finding little tricks and hacks that help people do their job much faster, or having people start working a little faster than they were before. If you really want to increase

-

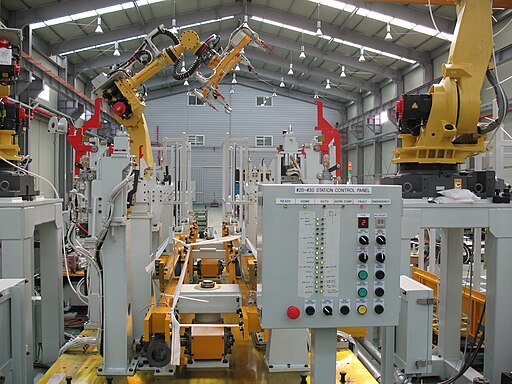

What are the First Steps a Manufacturer Should Take to Modernize?

- October 20, 2021

- Posted by: David Marshall

- Category: Digital Transformation, Innovation, Manufacturing

Last week, I talked about how there’s still a need for old-school manufacturing, but that doesn’t mean that there will always be a need. Some of you old-school manufacturers need to modernize and update your systems. If you’re still running labor-intensive processes and you’re struggling to find labor just to meet your orders, then maybe

-

Is There Still a Place for Old-School Manufacturing?

- October 13, 2021

- Posted by: David Marshall

- Category: Innovation, Manufacturing, Productivity

In these days of digital manufacturing and additive manufacturing, there’s still a call for old-school manufacturing with hydraulic presses, forging and extruding metal products, stamping and punching, and so on. There’s still a call for old-school manufacturing because there are some things that you just can’t automate. One reason is that you don’t have scale,