- January 20, 2021

- Posted by: David Marshall

- Category: Management, Measurement, Productivity

Your orders have leveled off and hit a plateau, but your operating costs are on the rise, which is cutting into your profitability. How can you increase revenue even while your average number of orders processed and units moved are remaining flat?

One of the ways you can do that is just by increasing your prices at least to stay ahead of the inflation.

After all, we’re experiencing inflation these days. Many of the things we buy — milk, bread, furniture, equipment, and cars — are all increasing in price. There are any number of reasons why that’s happening, but it all comes down to the fact that it costs more to make things, which means those price increases are being passed on to us.

If you’re a manufacturer, that includes the costs of your raw materials, utilities, and even your payroll costs. (Because your associates want a raise because everything is costing them more these days, too.)

So step one, increase your prices to at least match the inflation rate. Of course, you can increase your profits a little more just by pricing a little higher than the inflation rate. If your costs have risen by 3%, raise your prices by 5%.

Another way is to improve your productivity and increase the number of units you can produce in a day or in an hour. In other words, get more squeal out of the pig.

If you can reduce the costs of your internal handling and processes, and be able to handle more pieces per hour throughout your organization, you’ll be able to make the same number of units at a lower cost, which will increase your overall profitability.

A third way is to decrease the cost of production. This is a more complex problem than it sounds. If you’ve been in business for a while, you’ve established your processes and procedures. You know how many pieces you can make per hour, you know how to run the machines efficiently, and you know what it takes to produce your regular hourly rate — you’ve got it calculated to the penny, and you can’t budget it off that amount, no matter what.

Except maybe you can.

For one thing, if you’re not already doing it, you should be measuring everything. (Read my article on Optimizing Productivity Through Plant Workflow Measurement.)

For one thing, if you’re not already doing it, you should be measuring everything. (Read my article on Optimizing Productivity Through Plant Workflow Measurement.)

If you’re measuring everything, you know where the little peaks and valleys are in your productivity. You know where the downtime is, you know when machines break down, and you know when they’re about to breakdown. You know who your A players are, and who your C players are.

Start creating maintenance plans to prevent the breakdowns instead of waiting until (or past) the last minute to fix a problem. Downtime means down revenue, so avoid the problems in the first place.

Put your C players on improvement plans too. Get their productivity up, or replace them with someone who is more productive.

Finally, eliminate waste throughout the operation. This means reducing the number of errors in manufacturing, the number of rejects you have to dispose of, and the number of defects you’re causing.

Again, this is where measurement comes in handy. If you measure everything and everyone in the operation, you will eventually be able to figure out who or what is causing most of those problems. It could be a single person, it could be the way your raw materials are being stored, or it could be that one of your machines is malfunctioning.

It also means you should be looking in the back office and places off the floor as well. Measure the people in the administrative functions, because their mistakes can cause you a lot of lost revenue.

All of these things can happen concurrently, too. Don’t feel like you need to do one thing, and then another, and then a third. Start measuring everything and improve all the areas as you find them. Figure out how much the problems are costing you per incident or per unit. Calculate the improvements by multiplying the costs by the reduction of problems. That’s your revenue increase, and you did it all without ever-increasing the number of orders you take.

(Although there’s a good chance that reducing errors and improving quality are going to have a positive effect on the number of orders you get too, as your reputation for quality products goes up as well.)

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business, including finding ways to increae revenue. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

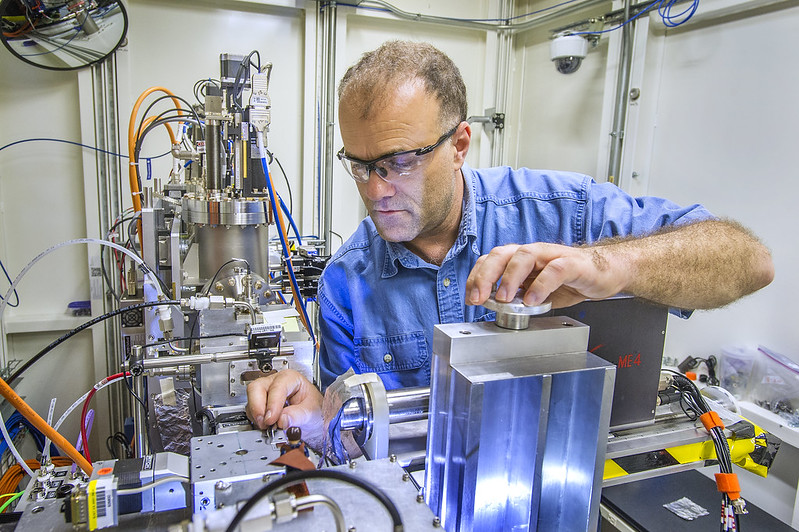

Photo credit: Brookhaven National Laboratory (Flickr, Creative Commons 2.0)