- January 19, 2020

- Posted by: David Marshall

- Category: Digital Transformation, Manufacturing

Industry Week recently asked what manufacturing will look like 50 years from now. Author Irene Patrick, senior director of the Industrial Innovation/IIoT Group, Intel, wrote about the eight driving factors that she thought manufacturers would be facing around 2070. It was an interesting prediction, and it’s a fun mental exercise to imagine the machines I used to manage, the advances in technology over the last 30+ years, and to see where that timeline could take us.

Patrick talked about things like measurement, digital dexterity, new business models, and the idea that “data will be king”as simulations will drive decision making.

For starters, Patrick said, measurement will still remain critical, and it will help improve productivity and reduce and downtime.

Predictive maintenance will be the norm and unplanned downtime will be drastically reduced. Moreover, individual machines can be run close to their tolerance limits since sensors will be able to identify the machine’s ability to meet part needs.”

Patrick also said 3D printing and additive manufacturing will be cost competitive, as they’ll be fully integrated and linked seamlessly with more traditional processes. Having overseen a digital transformation to a nearly fully-automated system, I would love to see what this could look like in 50 years, especially as we’re seeing 3D printing create objects in a matter of seconds, not many minutes. If we can do this in 2020, what will it look like in 2050?

People’s roles in manufacturing will also change. Since automation is bound to replace repetitive tasks, and can speed up and slow down as the orders demand, human workers will need to be more technically-educated, know how to maintain and program the machines, and won’t be required to do as much heavy lifting or wrench turning.

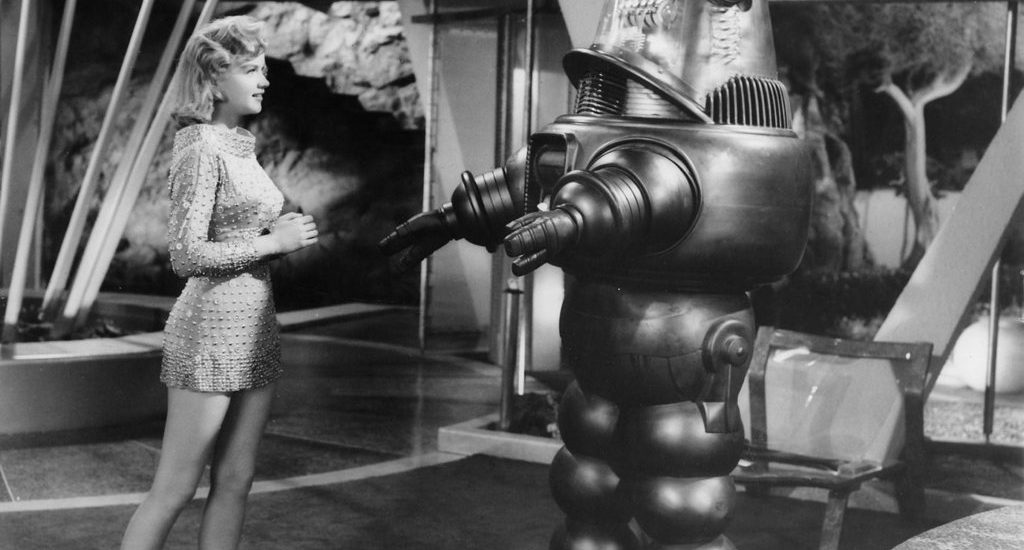

And AI will be more associated with augmented intelligence, where people and digital tools will be “tightly integrated.” We’ll have wearables and exoskeleton supports — remember the exoskeleton cargo mover/alien fighter from Aliens? — to increase our performance and improve our safety.

And AI will be more associated with augmented intelligence, where people and digital tools will be “tightly integrated.” We’ll have wearables and exoskeleton supports — remember the exoskeleton cargo mover/alien fighter from Aliens? — to increase our performance and improve our safety.

I think manufacturing will become a more automated version of what we have today. This means we will also see a need for advanced degrees and less high school education-only non-skilled labor. The degree holder will still have to turn a wrench and do some general labor, but it will be on the machines themselves, not the products going out the door. And depending on the type of production, there will be more lights out manufacturing as well.

I’m also looking for 3D printing to greatly improve, not only in the materials we’ll be able to print, but we’ll be able to do it faster. We already have a 3D printer that can print small items from a special resin in seconds, so what will be doing in 50 years? Fifty years ago, we were watching Star Trek’s depiction of food replicators as the pinnacle of replication/”printing” technology. Now we’re 3D printing rocket engine parts out of titanium and materializing small objects in seconds. How far are we from that instantaneous type of printing and fabrication that Star Trek predicted?

A lot of this advanced manufacturing technology is still in its infancy, and it’s only going to grow and improve. New technologies will be invented, current ones will improved or discarded, and everything will be done faster, cheaper, and safer than we’re doing it now. I only wish I could be around to see it.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

Photo credit: Picryl.com (Public Domain)