- May 22, 2019

- Posted by: David Marshall

- Category: Digital Transformation, Manufacturing

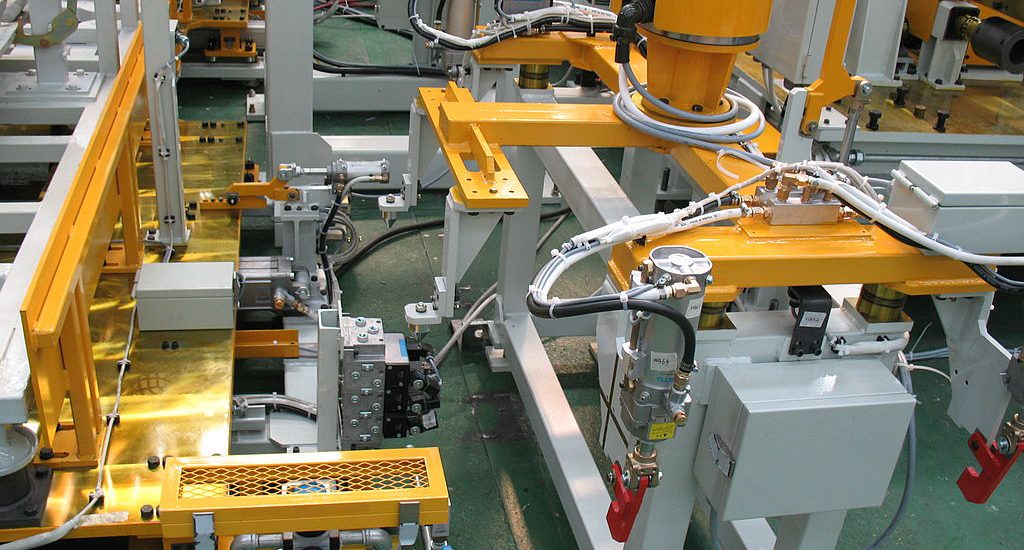

Taking on a digital transformation — not just switching from an analog process to a computerized one — but actually transforming your manufacturing process from a staff-and-labor driven process to one that’s managed more by computers is going to be a serious undertaking.

We underwent a digital transformation at a Duoline factory I ran several years ago. We had a factory that employed 140 people, cost as much as $1 million in environmental remediation and $2.5 million in waste.

We tore the entire thing down and started over with an nearly-fully-automated process that employed 20 people, cut our remediation costs to $0, and our waste to less than $10,000 per year.

Of course, we learned several important lessons along the way.

1. You may lose staff in a digital transformation.

Right or wrong, automated equipment and artificial intelligence will reduce the need for low-skill, repetitive jobs. You no longer need people to move raw materials into position, or move partially-completed products to another machine if you’ve got an automated system that can do it all for you. You can set up your production line so all the machines move in order of production, and have them automatically moved between machines, rather than relying on your associates to do it.

Right or wrong, automated equipment and artificial intelligence will reduce the need for low-skill, repetitive jobs. You no longer need people to move raw materials into position, or move partially-completed products to another machine if you’ve got an automated system that can do it all for you. You can set up your production line so all the machines move in order of production, and have them automatically moved between machines, rather than relying on your associates to do it.

This worked to our benefit because we had several employees who were less-than-ideal employees in our old system. We kept and retrained the best employees to work in the new system and they helped the new factory run very well.

2. You’ll need specialized staff.

Of course, this also means you’ll need people who are capable of running the new machines. For example, if you buy a new CNC router for your production line, or replace a few manufacturing machines with a 3D printer, you’re going to need people who know how to operate and maintain those machines.

While you may have been paying someone $20 per hour to be able to operate the old systems, your new operator may earn as much as $50 – $75 per hour. Of course, the new system will be faster than the old one, and you may be able to cut down on overtime or even an entire shift, and end up saving more money by employing one specialist rather than four or five generalists.

Consider retraining your old staff rather than conducting national searches for those highly-skilled specialists. Your old staff will understand how things are supposed to be done, and you’ll already be a few steps ahead in staffing up your new operation.

3. You need to measure all progress.

Digital transformation requires that you measure everything. How else are the machines going to be able to perform effectively? And how else will you know whether the digital transformation is actually meeting its project goals?

When we built the new Duoline factory, each work cell could capture 44,000 pieces of data per shift. We had four cells in our factory, which meant we were gathering 176,000 pieces of data per shift. From there, the data was shared through our measurement dashboards. We would watch things like production rates, critical steps in the manufacturing process, and even the status of the equipment itself. And we were able to measure how quickly and easily the new system was paying for itself.

4. You need buy-in from the top executives

If you’re not one of the top executives leading the digital transformation yourself, you’re not going to get very far if you haven’t been given carte blanche decision making over the entire operation. That means that not only do you make the decisions and implement the new policies, you have to be given time to iron out all the wrinkles in the inevitable shakedown period.

There will always be problems when you make any major change in your organization, and turning an analog operation into a digital one is one of the biggest you can do. I remember once when we changed out one of our ERP systems and people weren’t having it. I was ready to scrap the entire system until our controller sat me down and explained that the problem wasn’t the system, it was the users who were not trained in its proper usage.

So I required everyone in their jobs to create written procedures for their own function within the new system as a way to ensure they were using it properly. But if we hadn’t had my buy-in, I would have turned a difficult solution into a very expensive failure.

Too many executives will fold a change or revamping of processes if they see things aren’t going well, rather than requiring everyone in the company to embrace the new change and move on.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business, especially for digital transformation. If you would like more information, please visit my website and connect with me on Twitter, Facebook, or LinkedIn.

Photo credit: Mixabest (Wikimedia Commons, Creative Commons 3.0)