- February 7, 2018

- Posted by: David Marshall

- Category: Innovation, Manufacturing

Believe it or not, automation and robotics are going to improve our economy and our employment numbers, and can even help improve the education of our workers.

U.S. unemployment is low, we have a vibrant economy, and we’re likely to have selective immigration, which means if we’re going to continue to grow, we need to improve productivity. To do that, you can’t just tell someone who’s producing 10 widgets per hour that they have to up it to 20.

For one thing, most manufacturers and associates already know what they have to produce, and they’re already producing it as fast as they can. Of course, you have to measure all this to be sure, but for the sake of argument, let’s assume that everyone is pretty on the ball.

This means that you have to find new ways to produce those additional 10 widgets. You can’t just hire another worker because unemployment is already low. And if the person is working as fast as they safely can, they’re not going to be able to double their output.

So we need automation as a way to improve that productivity.

Several years ago, I worked to rebuild an entire factory that was running inefficiently, was creating a lot of pollution, and lost 20% of its workforce whenever we had a random drug screening. To top it off, we had 140 people in the plant. So we built a brand new factory over two-and-a-half years, added new machinery, new processes, and new automation technology, and we increased total output with only 20 associates.

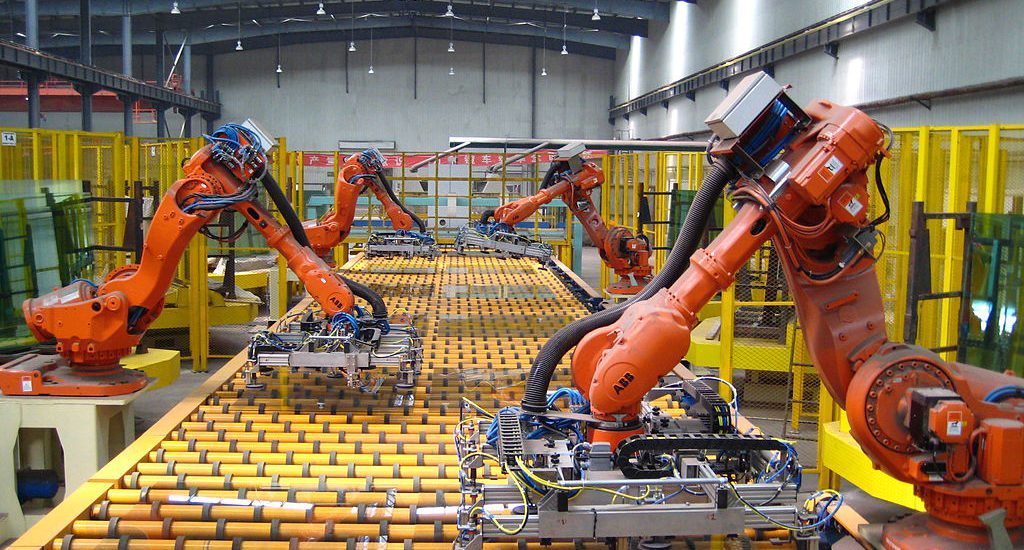

Automation Will Play a Bigger Role in Everything We Do

But automation won’t necessarily replace workers. For one thing, we still need people to feed the machines, manage the supplies, and package up and ship the finished products. But more importantly, there are people who will be needed to maintain the machines, repair them, and ensure everything is running smoothly.

But automation won’t necessarily replace workers. For one thing, we still need people to feed the machines, manage the supplies, and package up and ship the finished products. But more importantly, there are people who will be needed to maintain the machines, repair them, and ensure everything is running smoothly.

All in all, automation is only going to add new jobs. For example, automation has replaced 800,000 workers in the UK, but it created 3.5 million new jobs.

Of course, this doesn’t mean a one-for-one trade. Automation is going to replace general physical labor, such as mining or even driving. But this will create more jobs for people who are qualified, such as having decent math and computer skills. According to the IEEE blog:

And those looking for jobs at a factory need to have computer skills now. Yet fewer than 15 percent of the 10,000 applicants who attended a job fair at Siemens Energy, in Charlotte, N.C., were qualified for positions at the company, with ninth-grade level reading, writing, and math skills, according to The New York Times. The article goes on to say John Deere also has trouble filling its factory positions, because building and fixing tractors and grain harvesters now requires advanced math and comprehension skills.

This means we need to focus more on worker retraining and education, improving STEM education in our school systems, and even ensuring more kids get into college. We need to focus on creating more engineers than lawyers because we’re going to have to learn to make things bigger, better, faster, and more reliable than ever before.

For example, while you don’t need a college degree to become a CNC operator like you did 20 years ago, but you probably do need one if you’re going to program it.

For example, you can create recipes that will let you do certain things, such as cutting 20 mm ovals out of a sheet of steel. You just choose the recipe, press the button, and feed the machine. Twenty years ago, you would have had to program that recipe, but now that’s been turned into a few simple steps with a few buttons. So while anyone can operate a CNC machine now, it’s the people who know how to program it that will have a more secure future.

You can also get the kind of special training and certification from your local community college that would let you calibrate and repair these new machines. Any piece of moving equipment needs to be calibrated and readjusted, worn parts need to be replaced, and you need to assess the output of the machine as the moving parts wear down over time.

Plus, if a robot decides to go rogue, it’s going to damage a lot of material and leave you with a lot of scrap. A robot is only as good as it is consistent.

So the technicians who monitor and manage the robots are the future of manufacturing. These are high-paying jobs that require high-tech skills.

In the end, robots aren’t going to eliminate jobs like it’s a zero-sum game. They’ll create jobs. But these are different jobs that can’t be outsourced, off-shored, or replaced by more robots. If you want to be a part of the future, this is a good excuse to get some additional education, training, and certification, and protect your job and economic future as more manufacturers turn to automation.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business. If you would like more information, please visit my website and connect with me on Twitter or LinkedIn.

Photo credit: ICAPlants (Wikimedia Commons, Creative Commons 3.0)