- January 25, 2017

- Posted by: David Marshall

- Category: Business, Manufacturing, Measurement

An organization needs a good customer service department, but their job could be a whole lot easier if the organization itself focused on “never having to say they’re sorry” as well.

I don’t mean adopt an uncaring attitude that ignores a customer’s issues. I mean deliver a quality product on time at a fair value every time, and do it right the first time.

If you can achieve that as an organization, you won’t need to apologize, because there will be nothing to apologize for.

If you can achieve that as an organization, you’ll soon discover you have more salespeople than customer service people. You’ll have more opportunities to chase than you have problems to fix.

But if there is a problem, overreact to it. In other words, blind the customer with speed, accuracy, and sincere concern, because it will save that relationship.

For example, if there was ever a job site complaint at Robroy, my rule was somebody had to physically be there at the customer’s site within 24 hours so we could fix the problem, and it didn’t matter where in the world it was. If possible, we showed up with part in hand to make the repair. If not, we diagnosed the problem and came up with a quick solution.

If your job site is in San Francisco or London, and some part we produced didn’t fit, that’s not the normal expectation. That means we had to have someone there the following day, and that is not the normal expectation either. That someone could be someone from manufacturing, sales, engineering, or whoever could easily solve the problem.

Now, 99 percent of the time, just by physically doing that, we eliminated present and future relationship issues.

They knew we cared, they knew we valued them, and they knew we were working to deliver a quality product on time at a fair value. As a result, they were willing to forgive us the occasional error, as long as we fixed it right away.

I think everyone has had the experience of buying something, taking it back to the store, and then jumping through a number of hoops just to get the problem fixed or the item returned. We’ve all gone through it so many times that it seems normal, which is why our approach at Robroy seemed so unusual.

Think about what happens when your wifi goes out. You call customer service, wait for 30 minutes, have them walk you through all the steps, which takes another 30 minutes, before your problem is finally fixed. (It’s even more frustrating when you already did those initial steps before you called, and they still make you walk through them all.)

But if someone could deal with your problem immediately, and without all that hoop jumping, your level of satisfaction would be an awful lot higher. If they could just diagnose your problem more quickly, or even reboot your router for you — or even let you jump to the next level technician if you’ve already done those initial steps yourself — you’d be much happier with your cable company.

Are you measuring the right things in your customer service department?

Many customer service departments and call centers will measure their performance, but they’re not necessarily measuring the right factors. They focus on the amount of time an agent spends with one call — the shorter the better — or the number of calls per hour, or a performance survey of the caller’s satisfaction with that agent.

But they don’t measure whether the company fixed the issue, whether they avoided the issue, or even how long it takes to fix the problem. They don’t take systemic problems into account, only how quickly the agent moved on to the next call.

The whole reason you should be measuring customer service is to determine the true root cause of the problem and eliminate it.

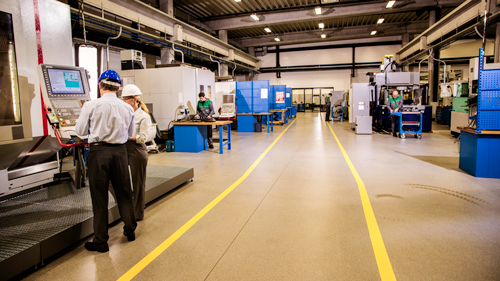

How many customer service “problems” were actually a result of poor manufacturing? How many of these problems could have been avoided if the system had been installed properly? What if someone in the quotations or order entry departments transposed a part number, and the wrong part was delivered?

Customer service issues can be created by poorly-designed or defective products, or a lack of validation within the process to ensure accuracy. The problem can be a product issue, or it can be a people issue, but you won’t know if you’re only measuring call times and caller satisfaction.

Yet it’s the customer service department who bears the brunt of the customer’s dissatisfaction, while the individual departments who created the issue rarely hear a word. (So they’re caught completely unaware when orders drop off because customers are switching to new vendors.)

But by doing two things — getting it right the first time, and responding quickly when you don’t — it creates a loyalty in the customer who had the problem. Because you changed their experience, you become top of mind whenever there’s a new opportunity. And you made life easier for the customer service department to begin with.

This is why good customer service needs its own blinding speed and accuracy as a way to retain their customers. This is why customer service needs to be able to handle problems with an eye toward keeping their customers happy and loyal.

But this also shows why the manufacturing department, the quotations and entry order people, and even the warehouse staff are all in the customer service and solution business. And why the customer service department should be looking at root causes instead of call times.

I’ve been a manufacturing executive, as well as a sales and marketing professional, for a few decades. Now I help companies turn around their own business. If you would like more information, please visit my website and connect with me on Twitter or LinkedIn.

Photo credit: Holidayextras (Flickr, Creative Commons)